Sometimes in our industry, the words interceptor and trap are interchangeably used but they do mean two different things.

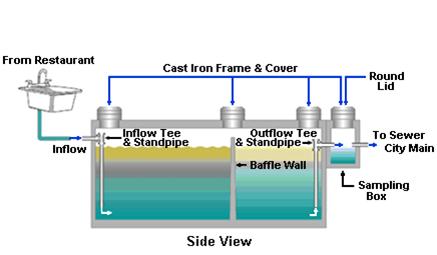

Typical Interceptor

Water is slowed down by the inlet downturn which allows for gravity separation of solids and fats, oils, and grease. Water flows through the baffles between each compartment further filtering out FOG and solids until “clean” water leaves the interceptor through the outlet downturn.

Typical Trap

Water is slowed down by the inlet baffle wall which allows for the separation of solids and FOG. Solids are blocked by baffles on the floor of the trap “Clean” water leaves the trap through the outlet baffle.

Improper Maintenance can allow material to leave the interceptor allowing FOG to enter the City’s sewer system. This may cause a blockage in the private line. Blockages can lead to Sanitary Sewer Overflows (SSO’s) or private blockages which may spill onto the outside of a facility or backup within the facility. Holes in traps can allow material to penetrate the ground beneath the facility.

No interceptor or trap is 100% effective at retaining grease, oils, solids, etc. The longer a device is left maintained, the more material can escape. As a material, such as a grease, leaves the device, it can coat the inside of pipes. This can lead to frequent costly hydro jetting of sewer lines.

When an interceptor or trap is not properly maintained:

Excess buildup of the contents can lead to blockages or surcharges.

Missing or broken inlet and outlet baffles and baffles walls do not allow efficient separation of grease.

Grease entering the City sewer systems can back up causing Sanitary Sewer Overflows, Blockages, and Stoppages.

Surcharging and blockages may prevent your establishment from opening until the issues are resolved.

Grease over time becomes acidic and can corrode and destroy your interceptor or trap.

What is Interceptor Maintenance?

For an interceptor to work efficiently it needs to be completely pumped out and cleaned periodically. Most types of interceptors stop working effectively when fats, oils and solids reach 25% of the device’s capacity.

How often should I pump my interceptor?

Every 30 days for a grease trap

Every 90 days for a grease interceptor

Every 6 months to annually for lint or a sand/oil interceptor.

Your interceptor may need more frequent pumping depending on how much sand, oil, fats, and solids your facility produces. The less you put down your drains the less often you will have to pump.

If can’t remember the last time you had your trap or interceptor pumped, it’s probably time for it to be done again. In the City of Phoenix, (and most surrounding towns) pumping records are required to be on-site for a minimum of 3 years for inspectors to review. When you schedule regular services with Priority Pumping, we will provide a folder and digital invoices for you to store your pumping records for handy reference when, not if, your inspector rolls around!